So this is information for the last ditch effort. You are not able to find any form of Penicillin or it’s related formulaic cousins anywhere, and there is no hope to either get it, or have it available any time soon. Here’s a way to produce this antibiotic if there is no other option. Put on your chemist hat on and get your surgical gloves on and let’s get making!

Discovering the Power of Penicillin: A Guide to its Production and Uses

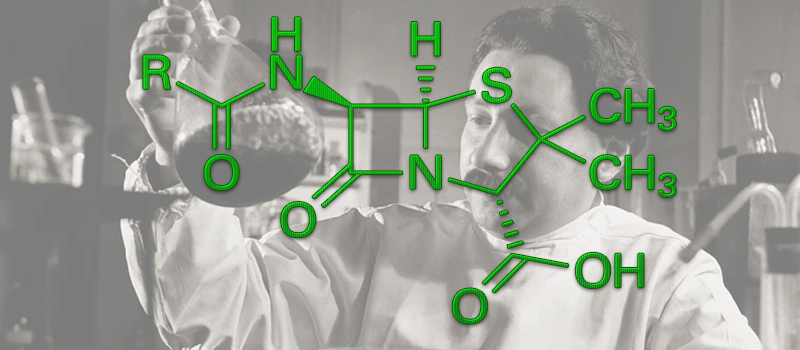

Penicillin stands as a testament to the marvels of modern medicine. In an era where the scarcity of this antibiotic was so profound, its value soared to unprecedented heights. Patients’ urine was collected during treatment to isolate and recycle the precious penicillin therein. Such was the significance of knowing how to produce this life-saving drug.

Unveiling the Potential of Penicillin

Penicillin, a groundbreaking antibiotic, combats bacteria, fungi, and microbes within the human body. Its discovery in 1933 marked a pivotal moment in medical history, earning its name from “anti” (against) and “bio” (life).

Understanding Penicillin’s Versatility

Contrary to common belief, penicillin isn’t solely for treating colds. It serves as a potent remedy for a spectrum of ailments including Typhoid Fever, Syphilis, Pneumonia, Meningitis, Anthrax, Tetanus, Tuberculosis, Chlamydia, Abscesses, Leptospirosis, and Lyme disease. Its efficacy against infections, even from minor cuts, cannot be overstated.

Crafting Penicillin at Home: A Step-by-Step Guide

1. Cultivating Penicillin Fungus

Initiate the penicillin production process by cultivating the Penicillin fungus. Exercise utmost care to maintain sterile conditions throughout the procedure. Expose a slice of bread to the air in a dark, humid environment at 70°F until a vibrant bluish-green mold emerges, a process spanning 7-14 days. Transfer the developed mold to a sterilized flask and allow it to incubate for approximately a week under similar conditions.

You can also make penicillin the same way out of the peel of citrus fruits, cantaloupe or salami.

2. Preparing the Solution for Penicillin Extraction

Prepare a solution to extract penicillin from the fungus. Dissolve specific ingredients sequentially into 500ml of cold tap water, including:

- Lactose Monohydrate – 44.0 grams

- Cornstarch – 25.0 grams

- Sodium Nitrate – 3.0 grams

- Magnesium Sulfate – 0.25 grams

- Potassium Phosphate Mono – 0.50 grams

- Glucose Monohydrate – 2.75 grams

- Zinc Sulfate – 0.044 grams

- Manganese Sulfate – 0.044 grams

Then add enough cold tap water to make one liter. Use Hydrochloric Acid to adjust the pH between 5.0 and 5.5.

3. Extracting the Penicillin Substance

Pour the solution into sterilized milk bottles, ensuring the media level doesn’t reach the bottle’s plug. Add a tablespoon of the cultivated spores. Incubate the bottles at 70°F for 7 days. Filter the media, refrigerate, and adjust the pH to 2.2 using Hydrochloric Acid. Mix with cold Ethyl Acetate and separate the solution. Add potassium acetate, and wait for the ethyl acetate to evaporate, leaving behind Penicillin powder.

Innovations in Penicillin Administration

The resulting penicillin, when administered, demonstrates rapid excretion, with 80% eliminated within three to four hours. To prolong its activity, scientists combine penicillin with probenecid, inhibiting its excretion and enhancing concentration.

How to Test Homemade Penicillin Before Using It

Although you did probably make mold growing on the bread, it is possible you also got other molds. Even with the right kind of fungi growing, filtering out everything but the penicillin is difficult.

In order to be sure that you did make penicillin and not a toxic substance you have to test it!

Antibiotic activity may be measured in a crude way by making a mold of agar in a petri dish with tiny depressions, introducing a drop of penicillin broth into each depression, inoculating the plate with a known, penicillin-susceptible bacteria, and observing the area of inhibition from the penicillin-laced depressions over several days, compared to controls into which only water has been introduced before inoculation.

If the result is positive, I suggest, before taking it, to try it on an animal in small quantities just to be perfectly sure it’s not harmful. In case you have a sick animal try it on it and see the results. It might get better very shortly!

Now this is assuming you have any of the equipment necessary to do this, AND that you can keep it as sterile as possible. If it isn’t in the cards, you can get back to the natural way that you can gain the antibiotic properties without all the chemical hoops to jump through.

In conclusion, the production and utilization of penicillin have revolutionized the treatment of infectious diseases. While contemporary pharmaceutical methods have evolved, the fundamental process of penicillin production remains a testament to scientific ingenuity and perseverance. The penicillin made from this type of experiment should not be used unless it is a survival situation.